Configure Now

Items in Your Cart0

0Items in Your Cart

Start building your packageShop Now

Clean, readily available water is absolutely imperative for our health and well-being. A massive part of water maintenance is the regular cleaning of storage tanks. Over time, sediment from particles and minerals in the water sink to the bottom of the tank, eventually creating a layer of sediment or sludge which can impact both the quality of the water and the structural integrity of the tank.

Standpipe water towers typically represent the most straightforward approach to elevated water storage when dealing with lower capacities. These ground-supported structures closely resemble upright pipes, aligning with their namesake.

This straightforward design offers the advantages of a modest initial expense and a space-efficient solution for housing significant water quantities. However, the standpipe design does present its share of challenges.

This straightforward design offers the advantages of a modest initial expense and a space-efficient solution for housing significant water quantities. However, the standpipe design does present its share of challenges.

Given the substantial surface area relative to volume, standpipe water towers face challenges related to weather-induced fluctuations in water temperature, impacting water quality and causing thermal stratification issues.

Learn about the different types of industrial water tanks and how preventive maintenance reduces the tank's deterioration over time.

The additional elevation of the standpipe tank enables it to harness gravity's force to sustain adequate water pressure, facilitating the effective distribution of water stored within its reserves. The gravity-driven pressure system eliminates the necessity for a pumping mechanism, resulting in significant cost savings and positioning standpipes as one of the most cost-effective storage tank alternatives available.

Standpipe tanks offer a high degree of customization, allowing you to tailor the tank's height to meet seismic, diameter, and loading requirements.

Standpipe tanks are typically constructed from factory-coated epoxy and glass-fused bolted steel materials, ensuring their long-lasting durability. Unlike lower-quality tanks that may require frequent replacement, these tanks are designed to stand the test of time.

Their robust construction virtually eliminates the risk of leakage and significantly reduces the likelihood of damage. Furthermore, the bolted steel construction provides effective protection against thermal stratification, a common issue in standpipe tanks due to their increased height, which exposes them to more sunlight and, consequently, heat. Standpipe tanks are among our most dependable and resilient designs.

Cleaning standpipe water tanks is essential to maintain water quality and ensure the safety of stored water. Over time, sediment, debris, and contaminants can accumulate inside the tank, leading to potential health risks and water quality deterioration.

Cleaning standpipe water tanks is essential to maintain water quality and ensure the safety of stored water. Over time, sediment, debris, and contaminants can accumulate inside the tank, leading to potential health risks and water quality deterioration.

Regular cleaning helps prevent issues like bacterial growth, algae formation, and the buildup of sludge, all of which can compromise the purity and safety of the water supply.

Regular cleaning of standpipe water tanks is crucial for maintaining water quality and ensuring the safety of stored water. Discover why this practice is essential for health and longevity.

Standpipe water tanks, if not cleaned regularly, become breeding grounds for harmful microorganisms like bacteria, algae, and fungi. Learn how routine cleaning inhibits microbial growth, preventing health risks associated with waterborne diseases such as typhoid, legionella, and malaria. Routine cleaning and disinfection inhibits the growth of these microorganisms, ensuring that microbes are reduced and the formation of biofilms caused by stagnant water is prevented, and the water remains safe for consumption.

The World Bank estimates that approximately 1.8 million people die each year from diarrheal diseases linked to unsafe water and poor sanitation. Regular tank cleaning can help reduce the risk of waterborne diseases by ensuring clean and safe drinking water.

The American Water Works Association (AWWA) notes that the accumulation of sediments and corrosive elements can result in costly repairs and premature tank replacement.

The buildup of sediment, debris, and corrosive agents inside the tank can result in structural degradation and corrosion. Failing to conduct proper cleaning procedures can substantially diminish the tank's longevity, potentially necessitating expensive repairs or early replacement. Consistent and thorough cleaning plays a pivotal role in safeguarding the tank's structural integrity, ultimately prolonging its effective operational lifespan.

Maintaining water quality is vital to meeting health and safety standards. Unclean tanks can compromise water quality, leading to potential violations of regulatory guidelines. Regular cleaning helps ensure that water quality is consistently within acceptable limits, reducing the risk of non-compliance and associated penalties.

Various regulatory bodies, such as state and federal agencies, have guidelines and regulations for water quality and tank maintenance. Non-compliance can result in fines and penalties.

During the cleaning process, inspectors can identify potential issues such as leaks, cracks, or material deterioration. Timely detection of damage allows for prompt repairs, preventing more extensive and costly problems down the road. This proactive approach helps safeguard the overall functionality of the tank.

During the cleaning process, inspectors can identify potential issues such as leaks, cracks, or material deterioration. Timely detection of damage allows for prompt repairs, preventing more extensive and costly problems down the road. This proactive approach helps safeguard the overall functionality of the tank.

Sediment and debris in a water tank can also displace a significant volume of water, leading to water loss. According to the U.S. Environmental Protection Agency (EPA), water loss due to sediment buildup can be as high as 20% of the tank's capacity.

Various methods are employed to effectively remove sediment, contaminants, and debris that can accumulate inside these tanks over time. From manual cleaning procedures to advanced technologies like underwater ROVs (remotely operated vehicles), each method serves the vital purpose of preserving the safety and reliability of the water supply system. In this section, we will explore some of these methods used for cleaning standpipe water tanks and their respective advantages and applications.

Manual cleaning is one of the traditional methods used for cleaning standpipe water tanks, particularly in smaller tanks where access is relatively straightforward. Trained personnel enter the tank and physically remove sediment, debris, and contaminants. This method often involves the use of tools like shovels, brushes, and squeegees. While effective for small tanks, it can be labor-intensive and time-consuming.

The process involves draining the tank, entering and inspecting, scrubbing and cleaning with tools, disinfection, and finally, inspection and repair.

Suitable for smaller standpipe tanks with straightforward access. Allows for a detailed visual inspection of the tank's interior. Can be cost-effective for smaller tanks.

In larger tanks with deeper water levels, professional certified divers may be employed to enter the water tank and perform cleaning and inspection tasks underwater. Divers equipped with specialized cleaning equipment and underwater tools can effectively clean and inspect the tank's interior. This method is particularly suited for larger tanks where human entry is necessary due to depth, access restrictions, or complex structural features.

In larger tanks with deeper water levels, professional certified divers may be employed to enter the water tank and perform cleaning and inspection tasks underwater. Divers equipped with specialized cleaning equipment and underwater tools can effectively clean and inspect the tank's interior. This method is particularly suited for larger tanks where human entry is necessary due to depth, access restrictions, or complex structural features.

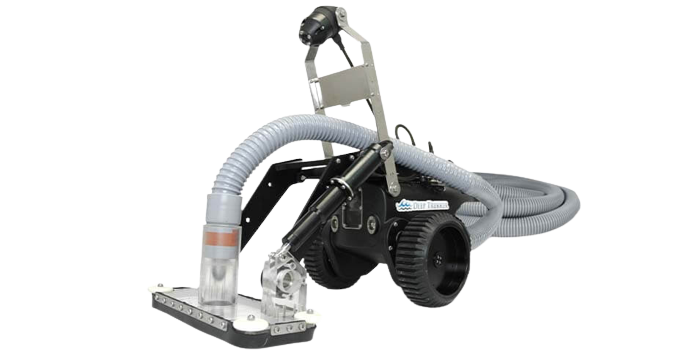

Underwater ROVs have revolutionized the cleaning of standpipe water tanks, especially for large or difficult-to-access tanks. These robotic vehicles are equipped with cameras and cleaning tools, allowing operators to remotely navigate and clean the tank's interior. ROVs are ideal for efficiently cleaning and inspecting tanks, ensuring thorough and consistent results without the need for human entry.

Underwater ROVs have revolutionized the cleaning of standpipe water tanks, especially for large or difficult-to-access tanks. These robotic vehicles are equipped with cameras and cleaning tools, allowing operators to remotely navigate and clean the tank's interior. ROVs are ideal for efficiently cleaning and inspecting tanks, ensuring thorough and consistent results without the need for human entry.

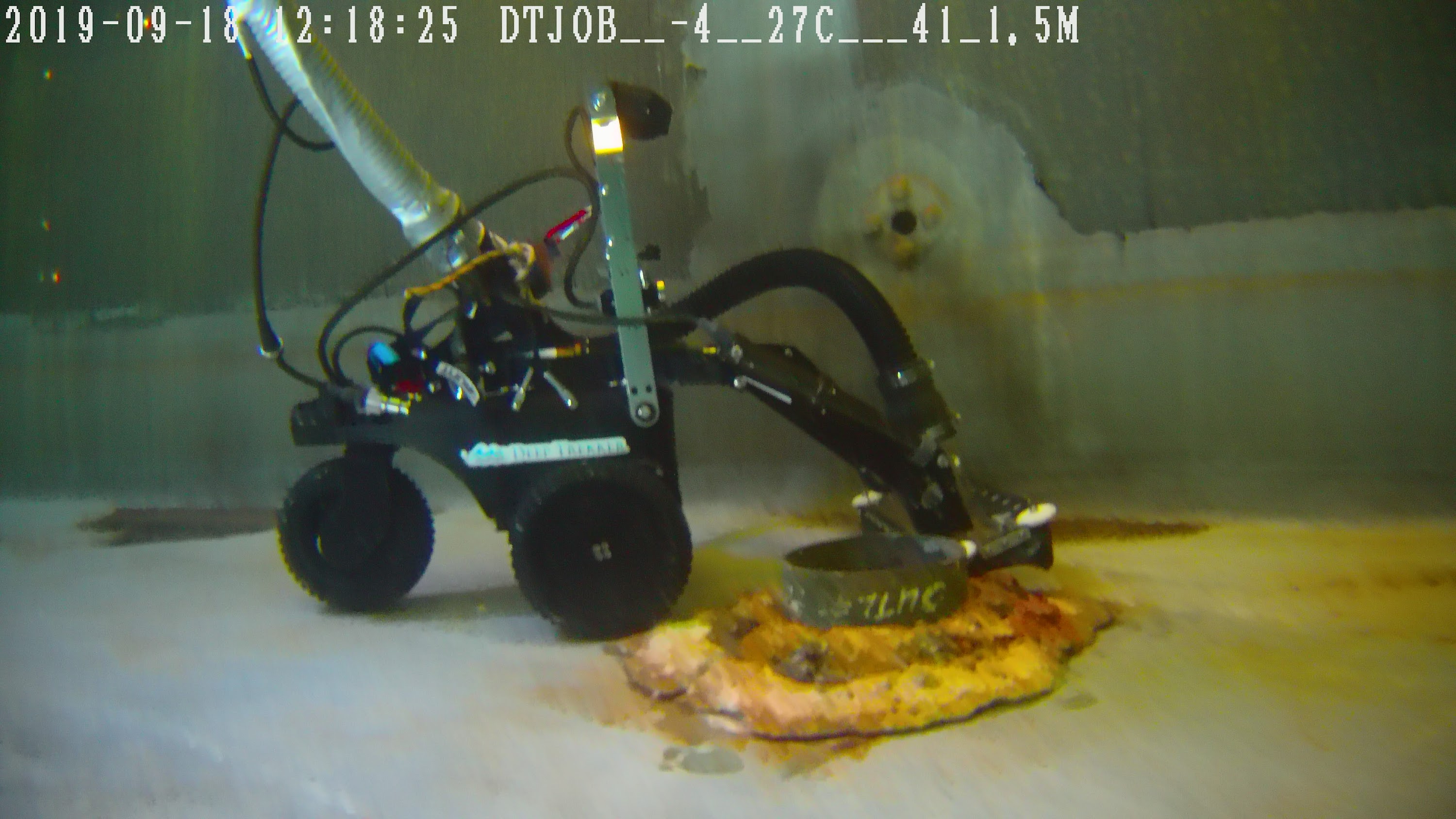

In an exclusive conversation with Robert Perrin of Ron Perrin Water Technologies, Inc., we delved into the transformative impact of deploying the Deep Trekker VAC crawler, affectionately known as "Wallie," for standpipe cleaning projects. Wallie has proven to be an indispensable asset, particularly for standpipes exceeding 100 feet in height.

Robert highlighted a significant shift in their cleaning approach, stating, "We use the vehicle instead of divers for tank cleaning." Previously, draining tanks for cleaning resulted in substantial water loss, up to 100,000 gallons. With the advent of the Deep Trekker VAC crawler, the Ron Perrin team now achieves efficient cleaning without taking the facility out of service, preserving valuable resources.

When opting for Deep Trekker, Robert emphasized pivotal factors in their decision-making process. Affordability played a crucial role, and the VAC crawler's lightweight design distinguished it from competitors, offering enhanced portability.

Portability is paramount for the Ron Perrin team, especially when navigating complex standpipe environments. According to Robert, transporting the utility crawler over 110 feet in the air and submerging it into the water demands a safe and efficient solution—the Deep Trekker VAC crawler perfectly fits this requirement.

The decision to use the VAC crawler instead of human divers is rooted in safety and efficiency. Robert explained, "We often deal with at least 100 feet of water, so the divers can’t stay down as long as the Deep Trekker can." This choice not only enhances safety but also ensures cleaning tasks are completed promptly.

Expressing satisfaction, Robert noted, "Our crew likes the vehicle; they think it’s fun to use." He emphasized the reliability and durability of the VAC crawler, highlighting its consistent performance as a crucial aspect of their operations.

Robert praised Deep Trekker's commitment to customer needs, stating that the company has "always taken care of our needs." The emphasis on customer experience is evident in the reliability, support, and functionality of the Deep Trekker products.

We extend our sincere thanks to Robert and Ron Perrin Water Technologies for sharing their story. For further updates, you can follow Ron Perrin Water Technologies on Facebook, LinkedIn, and explore their blog. The innovative use of Deep Trekker VAC crawler showcases the intersection of efficiency, safety, and reliability in standpipe water tank cleaning.

In the realm of standpipe cleaning, the Deep Trekker VAC Crawler emerges as a purpose-built underwater ROV, meticulously designed to navigate and thrive in challenging underwater environments. This section unveils the distinctive advantages that position the VAC Crawler as the ultimate solution for efficient, reliable, and cost-effective standpipe tank cleanings.

Deep Trekker ROVs are meticulously engineered for adaptability, rendering them essential instruments across various sectors and applications. Crafted from top-tier materials like stainless steel, precision-machined anodized aluminum, and fortified with carbon fiber shielding, they exhibit remarkable durability, readily withstanding the harshest of conditions.

Experience swift deployment and operational efficiency with Deep Trekker ROVs. The VAC Crawler, powered by lithium-ion batteries, eliminates the need for a topside power source, enhancing portability. With advanced features like powerful LED lighting, real-time 4K video feed, 360-degree field of view, underwater imaging sonar, and seamless integration with sampling tools, it's equipped for comprehensive standpipe inspections and cleanings.

Our team of seasoned industry experts are ready to offer their expertise and address any queries you may have regarding the incorporation of submersible robots into your projects. Whether your operations involve water tank inspections and cleaning, salvage operations, underwater inspections, search and recovery missions, aquaculture, environmental monitoring, or many other applications, we are at your service to help you understand how our ROVs can be tailored to meet your distinct needs.

The Deep Trekker VAC Crawler is not just an underwater ROV; it's a transformative solution reshaping the landscape of standpipe cleaning. Elevate your approach to underwater inspections and cleanings with the efficiency, durability, and adaptability of Deep Trekker ROVs. Contact us to receive a customized quote tailored precisely to your project requirements. By incorporating Deep Trekker ROVs into your standpipe cleaning operations, you secure unparalleled safety, efficiency, and success in your underwater maintenance projects.

November 3rd, 2025

At REPMUS 2025, Deep Trekker’s ROVs validated real-world mine countermeasure capabilities...

July 5th, 2025

Deep Trekker’s new Tampa facility brings faster ROV repairs, in-stock parts,...

June 11th, 2025

Equipped with sonar and DVL, Deep Trekker ROVs are helping SES...