Configure Now

Items in Your Cart0

0Items in Your Cart

Start building your packageShop Now

The process begins with a 3D seismic survey to identify the location of oil and gas deposits. Once located, wells are drilled thousands of meters for collection, and pipelines are installed to transfer the retrieved oil and gas to processing facilities. Oil tankers can also be used as a primary method of transportation. Once the crude oil or gas is refined into usable fuels, the byproduct is then distributed to filling stations or directly to customers.

Depending on the depth, length, or size of operation, there are a variety of structure styles that can be used for offshore oil and gas.

Ideal for shallow depths, fixed platforms are directly attached to the sea floor. A steel leg design typically is attached to the sea bed via piles or footings, however it is also possible for concrete legs to rely on their weight alone for stability. Fixed platforms are generally chosen for long-term projects where it makes sense to construct a permanent structure.

Ideal for shallow depths, fixed platforms are directly attached to the sea floor. A steel leg design typically is attached to the sea bed via piles or footings, however it is also possible for concrete legs to rely on their weight alone for stability. Fixed platforms are generally chosen for long-term projects where it makes sense to construct a permanent structure.

Self Elevating Platforms are similar to fixed, however they have the benefit of added mobility. Rather than being permanently fixed to the ground, self elevating rigs have built-in moveable legs that can be raised or lowered to temporarily set up a drilling station. Since the rig still operates on physical legs, self elevating platforms are also limited to shallow waters.

Self Elevating Platforms are similar to fixed, however they have the benefit of added mobility. Rather than being permanently fixed to the ground, self elevating rigs have built-in moveable legs that can be raised or lowered to temporarily set up a drilling station. Since the rig still operates on physical legs, self elevating platforms are also limited to shallow waters.

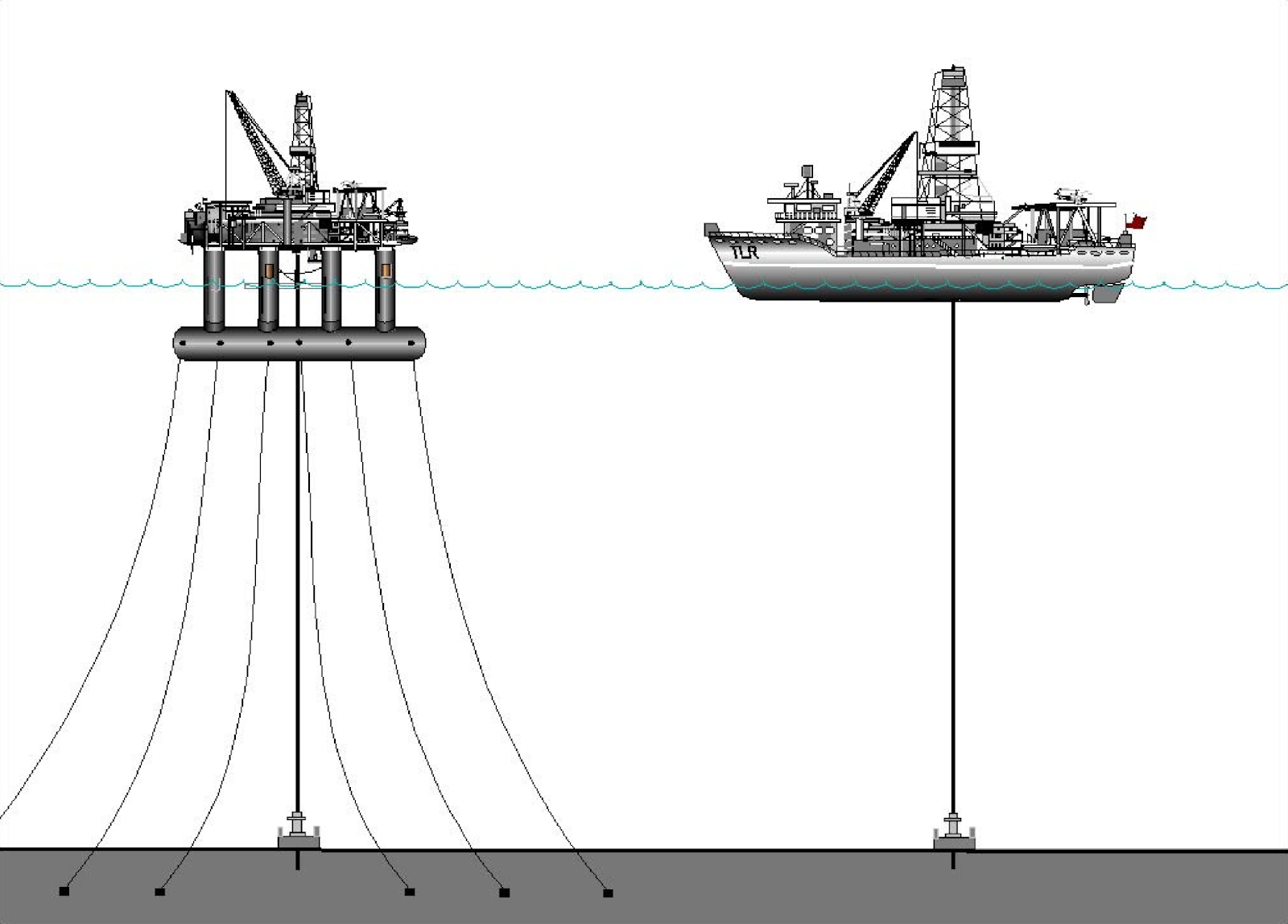

Diagram of semi submersible (left) vs. drillship (right)

Drillships, as the name suggests, are large vessels capable of offshore drilling operations. Capable of drilling thousands of meters, drillships offer benefits in portability as well as deep sea operation. Traditionally, drillships were also capable of mooring, however in modern practice, drillships have evolved to use advanced positioning systems to hold station. These systems will control the ship’s thrusters to combat natural forces, however stability is less in comparison to other drilling platforms.

A drilling barge, similarly to a drillship, floats on top of the ocean surface rather than mooring to the seafloor. Alternatively to a drillship, barges are not pilotable, making it necessary to tow these large floating platforms from place to place. Barges are generally only used for shallow or onshore drilling, since the hull is required to be brought to rest on the seafloor once positioned.

Interested in learning more about all the current offshore platforms? Check out our full article here

Many aged structures have suspected weak points and smaller leaks that over time become larger, creating worsening conditions for the structure. Leaks can be massive and catastrophic, garnering a lot of unwanted negative attention. Having an issue like Deepwater Horizon or Exxon Valdez has obvious environmental degradation, public backlash and safety compromises.

By implementing dedicated procedures of regular inspections, issues like suspected weak points or small leaks can be addressed before escalation. Building a consistent portfolio of pipeline inspection reports allows for effective asset status monitoring and more economical forecasting of routine repairs. As an end-state, this will result in higher efficiency and increased personnel safety for everyone involved, as well as surrounding areas.

Interested in learning more about all the current offshore platforms? Check out our full article here

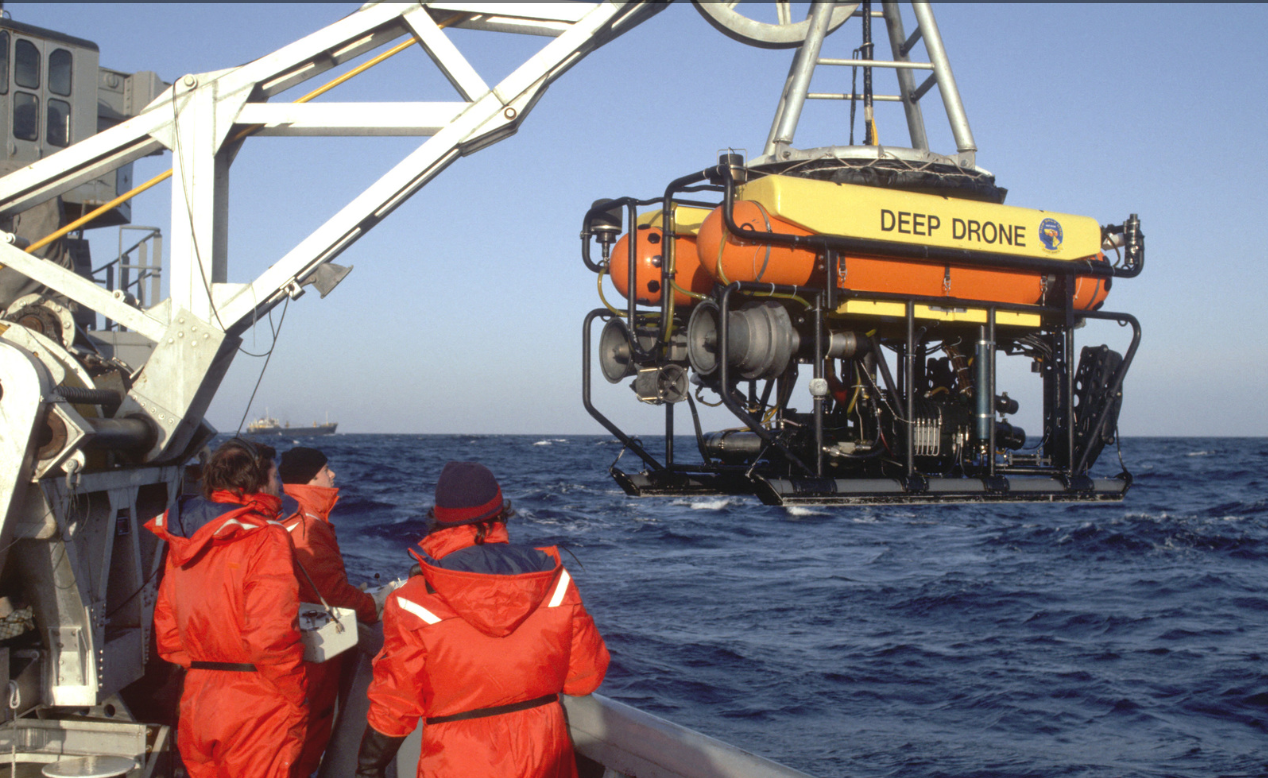

A work class ROV is used for ocean floor exploration and inspections at immense depths that divers are unable to reach. Capable of diving thousands of meters, these massive vehicles require full topside power generation and crane systems for deployment.

A work class ROV is used for ocean floor exploration and inspections at immense depths that divers are unable to reach. Capable of diving thousands of meters, these massive vehicles require full topside power generation and crane systems for deployment.

A light work class ROV is similar to work class, but at a slightly smaller form factor. Ideal for moderate to deep depths; the ROV is deployed from ships in lieu of divers to explore. It can be used during inspections to make repairs. Large extensions, such as laser scanners or specialized inspection devices and sensors, can be added on.

A light work class ROV is similar to work class, but at a slightly smaller form factor. Ideal for moderate to deep depths; the ROV is deployed from ships in lieu of divers to explore. It can be used during inspections to make repairs. Large extensions, such as laser scanners or specialized inspection devices and sensors, can be added on.

An Observation Class ROV is small in size and easily deployable by hand. They are often used for pre dive checks, conducting visual inspections, and can be equipped with sonar and custom sensors, for versatile applications.

An Observation Class ROV is small in size and easily deployable by hand. They are often used for pre dive checks, conducting visual inspections, and can be equipped with sonar and custom sensors, for versatile applications.

The micro or mini ROV is the smallest class, often used for simple inspections of hard to reach areas at shallow depths, such as pipe systems and submerged infrastructure. These lightweight and portable devices are easily transported and can still maintain impressive depths up to nearly 700ft.

The micro or mini ROV is the smallest class, often used for simple inspections of hard to reach areas at shallow depths, such as pipe systems and submerged infrastructure. These lightweight and portable devices are easily transported and can still maintain impressive depths up to nearly 700ft.

For optimal economic viability and ease-of-deployment, any pipelines at depths of 1,000ft or less can make use of observation class ROVs. These models generally range between $10,000 - $100,000 USD depending on the features and balance excellent inspection footage with portability. While ROVs may be unable to conduct most repairs, they are an excellent cost-effective tool for monitoring the entire lengths of pipelines. Operators can safely conduct and record inspection footage directly from the platform or off of a small rhib boat.

Aside from pipelines, ROVs can also aid in rig inspections. In open-ocean conditions, free diving can potentially be perilous, making ROVs the ideal solution for quick, safe, and effective underwater inspections. They are commonly used to inspect Hulls, Risers, Legs, Moonpool, Water, Cooling and Ballast Tanks, as well as sea chests.

Talk to us about how ROVs perform quality inspections of underwater pipes

Owning an ROV, especially an observation class, also opens up the door for much more frequent inspections. Deep Trekker ROVs set up in as little as 30 seconds, making it feasible to drop in for rapid inspections of a minor concern. Inspections can be day or night, and go on for as long or as short as needed without worrying about tallying costs. Ownership also enables custom reporting of important data for building a pipeline inspection history portfolio.

Adversely, inspection companies owning ROVs is a viable option for safer operations and maintaining competitive costs. Being able to have live video feed to show customers with location systems or imaging sonar can be the key differentiators between competitors.

Interested in reading more about the pros & cons of ROV ownership?

Recommended Article: Pros & cons of ROV ownership

Alternatively, for long-term projects where portability may not be beneficial, select models can be integrated with direct power for endless operation.

As always, our team of experts is available to answer any questions you may have. If you’re looking to upgrade your offshore inspections and lower recurring costs, reach out to get your customized quote today.

As always, our team of experts is available to answer any questions you may have. If you’re looking to upgrade your offshore inspections and lower recurring costs, reach out to get your customized quote today.

November 3rd, 2025

At REPMUS 2025, Deep Trekker’s ROVs validated real-world mine countermeasure capabilities...

July 5th, 2025

Deep Trekker’s new Tampa facility brings faster ROV repairs, in-stock parts,...

June 11th, 2025

Equipped with sonar and DVL, Deep Trekker ROVs are helping SES...

Interested in learning more about all the current offshore platforms? Check out our full article here