Configure Now

Items in Your Cart0

0Items in Your Cart

Start building your packageShop Now

Proper maintenance and sanitation are foundational in ensuring the fitness of stored water for its intended purposes, particularly when destined for consumption or culinary use. Implementing routine inspections emerges as a proactive strategy for early detection of potential concerns, encompassing leaks, contamination, structural compromise, or material deterioration—each posing risks to water quality and public health.

Proactive inspections not only detect issues but also facilitate essential maintenance and repairs, serving as a preventive measure against costly damages and contributing to the prolonged lifespan of water tanks. This practice becomes especially critical in industrial and municipal settings, where tank integrity is synonymous with ensuring uninterrupted water supply and robust fire protection systems

Adhering to periodic checks is essential to comply with safety regulations and environmental standards, emphasizing the indispensable role inspections play in preserving public health and ensuring the availability of clean and dependable water resources.

As a general guideline applicable globally, it is recommended to inspect and clean water tanks at least once every six months for drinking water and annually for non-potable water. This commitment to regular inspections stands as a crucial measure in preserving water quality and upholding public health standards on a global scale.

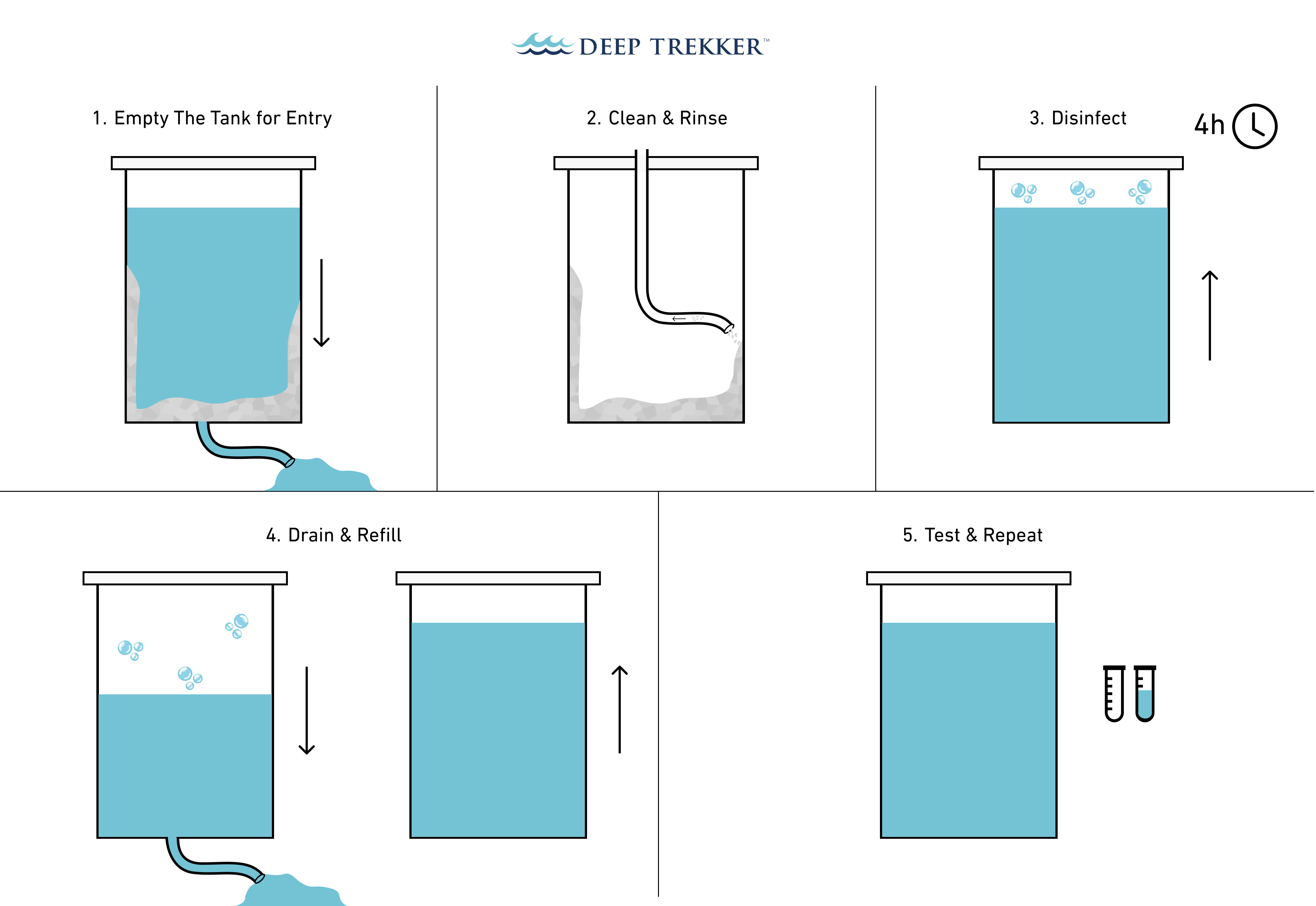

The most conventional method of cleaning a water storage tank involves a complete drainage, with certified workers entering and manually cleaning it. However, the entry of humans into the tank raises contamination concerns, necessitating the use of proper sanitary Personal Protective Equipment (PPE) and stringent disinfection of tools. The process comprises five steps.

Empty The Tank for Entry to allow for workers to enter and begin cleaning the tank. It must first be completely emptied of its water contents. Ensure that the water is drained into the ground away from plants for safe, legal disposal. All workers must be certified for working in enclosed spaces.

Cleaning and rinsing: Sediment is vacuumed, the interior is scrubbed with detergent, and pressure-wash rinsing is performed until all traces of detergent are gone.

Disinfection: A calculated ratio of water and chlorine-bleach is added, allowing a minimum 4-hour sitting time to disinfect the tank

Drain & Refill After disinfection, the tank is drained of the chlorine-bleach solution and refilled with clean water.

Test & Repeat Workers test water samples to ensure safe chemical levels; if necessary, the drain and refill process is repeated

Despite its effectiveness, this labor-intensive and costly method puts workers in potential danger, especially in confined spaces. Logistic and economic challenges arise as the tank must be taken out of service, requiring an alternative water supply to prevent shortages.

Despite its effectiveness, this labor-intensive and costly method puts workers in potential danger, especially in confined spaces. Logistic and economic challenges arise as the tank must be taken out of service, requiring an alternative water supply to prevent shortages.While pressure washing effectively cleans surface contaminants, it delivers lower quality results, with scale growth shortly after cleaning. Sandblasting and resurfacing due to corrosion are time-consuming and require certified contractors.

As an alternative to dry cleanings, commercial divers offer a method to clean water tank interiors without dewatering. Typically done in a team of three, one diver will enter the water while two remain topside as ‘spotters’. Before entering, the diver’s wetsuit is disinfected. Utilizing a vacuum system, the diver pumps sediment to the surface for removal and reports on the tank structure's condition

The primary advantage over dry cleaning is the ability to maintain water in the tank, preventing wasteful dewatering that can sideline water supplies for days. However, factors such as cost, risk, and time consumption should be considered when opting for divers in tank cleaning and inspections.

Divers undergo rigorous certification, contributing to high hourly costs. The dangers of confined space diving with single exits increase risks and premiums. Limited gas supply requires frequent resurfacing, extending cleaning times. While pre-entry sanitation is crucial, direct diver entry carries the risk of cross-contamination.

Cleaning water tanks is essential for maintaining water quality and preventing contamination, but it's not without its challenges. Particularly, when dealing with large, underground, or elevated tanks, the process becomes intricate and demanding. Challenges such as accessibility issues, sediment presence, biofilm formation, and the imperative need for thorough disinfection complicate water tank cleaning efforts. Effectively addressing these challenges is crucial to uphold the safety of stored water for diverse applications, ranging from drinking and cooking to industrial processes and emergency use

Traditional methods of water tank inspections and cleaning pose significant drawbacks, being labor-intensive, excessively costly, and time-consuming. Tanks often need to be completely taken out of service, introducing logistical and economic challenges. Workers face potential risks associated with confined spaces and toxic chemicals, with cross-contamination a looming concern. Divers, limited by gas supply, must frequently resurface, and certification, along with expensive insurance, is mandatory.

To alleviate or eliminate these challenges, alternative methods emerge, steering clear of traditional practices that involve divers and embracing advanced tools and technologies like Remotely Operated Vehicles (ROVs). Unlike traditional methods, ROVs offer the advantage of remote water tank inspections and cleaning, reducing labor intensity, costs, and time constraints. With the ability to operate without disrupting tank service, advanced technologies prove pivotal in overcoming the hurdles associated with conventional cleaning practices.

Implementing a Remotely Operated Vehicle (ROV) stands out as a highly effective option for inspecting and cleaning water tanks without the need for draining. Outfitted with HD cameras and the capability to equip multi-intake vacuum heads and pressure washers, these vehicles facilitate comprehensive tank cleaning remotely.

A primary advantage of Deep Trekker ROVs, in contrast to dry cleaning methods, is the ability to keep water tanks online. Amid growing concerns over water conservation, discarding substantial volumes of usable water poses significant challenges.

An illustrative example comes from Ron Perrin Water Technologies, which, after adopting a Deep Trekker VAC crawler, streamlined the cleaning process without wasting any water. Previously, they would drain a 110 ft standpipe of up to 100,000 gallons of usable water in order to clean the tank interior. After purchasing a Deep Trekker VAC crawler from Deep Trekker, they were able to accomplish this quicker and easier, while wasting zero water.

Learn about the importance of regular cleaning of standpipe water towers, and how ROVs can save time and money, and reduce risk to divers.

One of the major risks associated with sending divers into tanks is the chance of contamination from their equipment if they do not follow a strict procedure. There are a lot of “nooks and crannies” on a dive suit that can hold bacteria and other potentially harmful materials to the potable water.

For a Deep Trekker vehicle, disinfection is simple, reliable, and much faster than sanitizing dive equipment, thanks to their compact and intuitive design.

To disinfect, simply spread the vehicle and tether on a clean and disinfected ground sheet. Then, thoroughly spray down materials with a chlorine-bleach disinfection solution. Alternatively, the vehicle and tether can also be soaked in the solution. Note that all plastic ropes and cables, used to hoist a vehicle for example, must be treated in the same manner.

The portability of Deep Trekker's ROVs, operating on lithium-ion batteries, presents a significant advantage. With a compact setup that can be transported in rugged cases, these vehicles weigh only 34 lbs, allowing single operators to hoist them to the top of water towers. The handheld controller and tether system further enhance portability, replacing large control consoles and bulky tethers.

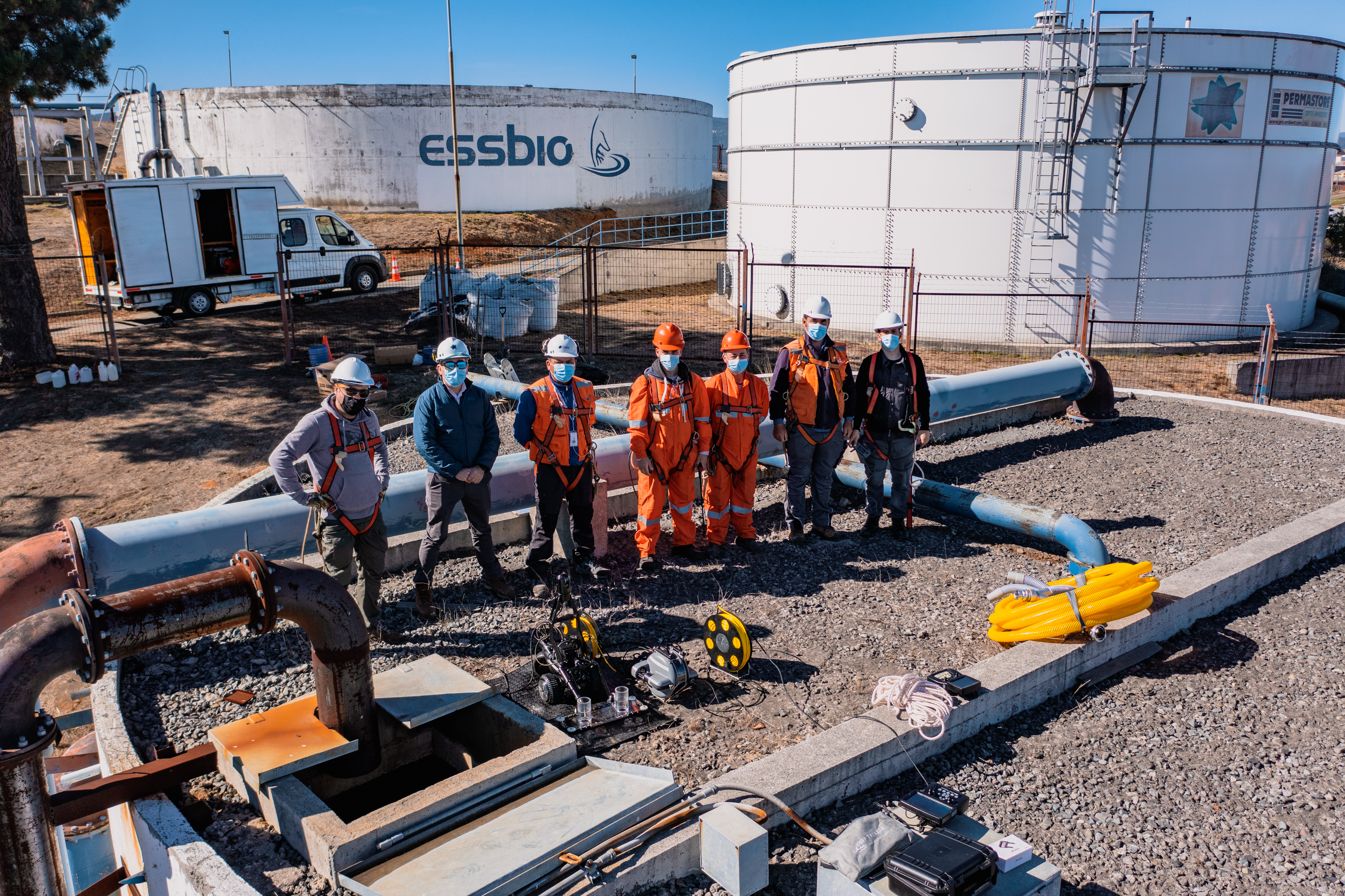

While acknowledging the continued relevance of commercial divers, the adoption of ROVs can effectively streamline tank cleanings, reducing costs, improving efficiency, and enhancing safety. The testimonial from The Tank Inspectors underscores the significant time and cost savings achieved by leveraging ROVs for tank inspections and cleaning.

While acknowledging the continued relevance of commercial divers, the adoption of ROVs can effectively streamline tank cleanings, reducing costs, improving efficiency, and enhancing safety. The testimonial from The Tank Inspectors underscores the significant time and cost savings achieved by leveraging ROVs for tank inspections and cleaning.

Learn about the different types of industrial water tanks and how preventive maintenance reduces the tank's deterioration over time.

ROVs significantly decrease the time needed for water tank inspection and cleaning. With quick deployment times and the elimination of the need to coordinate with divers, the efficiency of the process is substantially improved. The expertise of ROV operators ensures specialized inspections and cleaning, leveraging experience to conduct thorough and efficient evaluations.

Dan Hulands of The Tank Inspectors shared that with the ROV “there’s a lot less set up time, divers require a lot of set up.” Dan also went on to observe that, “the divers know about diving - they don’t necessarily know about tanks. All of our operators know about tanks and have been working with tanks for many years.” With the ROV, tank experts can get their eyes underwater, themselves, leveraging their experience and expertise to conduct specialized inspections and cleaning.

Furthermore, the portability of battery powered crawlers and ROVs allow for vehicles to be conveniently transported to a variety of locations within the same day - without the hassle of an external power source. Jeff Conway from the City of Independence noted, “Having a battery powered camera lets us take these vehicles wherever we need without the need of a generator for power”.

The elimination of the need for divers reduces long-term tank cleaning and inspection costs. The deployment and operation of an ROV only require one to two employees, and the ability to keep tanks in service without draining them enhances the overall effectiveness of the job. Since ROVs can be operated by internal staff, inspections become much more efficient. The pilots know exactly what to be evaluating and can quickly complete a thorough inspection.

As mentioned above, one of the most important benefits is that tanks can be kept in service and do not need to be drained in order to conduct an inspection/cleaning. Robert Perrin of Ron Perrin Water Technologies shared the convenience of using the Deep Trekker for standpipe cleaning.

“We use the vehicle instead of divers for tank cleaning,” he said. “Before we got the vehicle we would have to drain the tanks and the utility would lose up to 100,000 gallons of water.”

Michael McAloon, PE, Water/Wastewater Department Manager with Suburban Consulting Engineers echoed this statement, “The Deep Trekker is critical in providing inspection and condition assessment of water storage tank interiors, while maintaining normal system operations.”

The use of ROVs and crawlers eliminates the safety risks associated with divers. The use of submersible robots ensures that humans aren’t required to enter any confined spaces or potentially risky situations. The battery powered vehicle also limits contamination risk.

Since generators or other external power sources aren’t being used, Deep Trekker’s ROVs are convenient and also reduce the risk of spilling fuel or contamination. Finally, ROVs and crawlers are light and portable, with models as light as 10 kg (22 lbs). This makes them safe and easy for a single team member to transport and handle.

“It’s nice to save my divers from unneeded climbing or entry into a tank that was in good shape,” Jake Spaulding at Mountain West Commercial Diving adds, “It is so much nicer to hoist the ROV to the top of a tower than it is to send a diver dressed in heavy gear up a 65 ft ladder. Now we only send in divers if we know what is needed.”

Another considerable benefit of utilizing ROVs for water tank cleaning and inspections is the ability to collect and analyze data. With the attached high definition camera, ROVs can record and collect photos and videos during inspection, and this data can be transferred or stored easily for future inspection and analysis.

This provides documented historical data that inspectors can use to optimize cleaning and maintenance schedules proactively, which can help avoid costly repairs and shut downs. The reporting process is also much faster compared to manual documentation, since ROVs can compile the data and generate reports easily.

Teams can provide clients with professional and thorough documentation of their work. “The ROV is critical in assisting SCE with gathering the necessary information to identify tank deficiencies and problem areas. This information gathered is crucial in our report recommendation for appropriate rehabilitation measures, following tank inspection,” shared McAloon.

To start, users should first open their Pelican case and ensure that they have everything they need for the job. It is important that vehicles are given a quick once over to confirm that all required parts are intact and ready for use.

Next, the topside pump for the Deep Trekker VAC crawler should be connected and prepared.

Prior to putting the vehicle into the water it should be thoroughly cleaned to ensure safety and cleanliness for potable water sources. Both vehicles and tethers can be cleaned with a hypochlorite solution. This procedure is outlined in our handy step by step guide you can check out below:

Learn how to use an ROV to inspect your tank and disinfect it prior to deployment with our step-by-step guide to cleaning ROVs for potable water use

Once the vehicle has been cleaned and connected to the pump, cleaning the tank can begin. Using the lifting hook and rope, the vehicle can be safely lowered into the tank and the pump can be turned on.

Using the handheld controller, operators drive the vehicle on the tank floor to effectively and efficiently clean sludge.

Once the tank has been thoroughly cleaned, it can be inspected to ensure structural integrity. The use of ROVs such as the DTG3 or Photon is a safe and convenient method for conducting accurate and complete inspections.

The ROV can be driven around the tank to get a close up view of tank walls, floors, and roof. Furthermore, ultra high definition video and images can be captured to document any potential issues, and straightforward navigation allows users to get a complete picture of the tank.

Deep Trekker ROVs are an ideal solution for water tank cleaning and inspections. Their compact and portable design are perfect for entering confined spaces, with long lasting battery life, hybrid power options, a range of tether options up to 500m, and intuitive BRIDGE controller for enhanced capabilities and integration with advanced modular add-ons.

The Deep Trekker VAC crawler boasts a three wheeled design that enables a zero turn radius. A tilting and lifting actuator arm allows you to position your vacuum head in the optimal location to clean near corners, walls, pipes, etc., making it extremely maneuverable, even in tight, confined spaces.

The compact portability and intuitive controls of the VAC crawler combined with quick deployment capabilities and single person operation means that inspections and cleaning maintenance can be completed in a fraction of the time needed for divers to complete the same task.

Built for cleaning sediment and sludge from the bottoms of reservoirs and tanks, the VAC crawler is an easier, safer, and more cost effective alternative to utilizing divers for cleaning. The vacuum head connects to the VAC arch kit, holding the vacuum head out the front of the crawler. The main body camera provides a high-definition view on your controller that monitors the vacuum head's cleaning progress.

Connect a flexible 1.5” to 2" (38 to 50mm) hose to the intakes and the other end of the hose to a water pump. The actuators on the arch kit enable the vacuum head to rotate 20 degrees to get into corners or near obstructions like valves. The actuator also can raise and lower the vacuum head kit 20 degrees, or up to 2" (50mm) off the bottom of the tank. The 18" dual intake is the most popular option, as it balances being a size that fits in most areas and manholes of tanks while getting good coverage of the tank.

The DTG3 is a portable and cost-effective observation-class ROV designed for rapid deployment and dependable underwater inspections, capable of operating at depths of up to 200 meters (656 feet). This ROV is equipped with a full HD panning camera with a total view range of 270° that is ideal for inspecting confined areas.

The DTG3 is a portable and cost-effective observation-class ROV designed for rapid deployment and dependable underwater inspections, capable of operating at depths of up to 200 meters (656 feet). This ROV is equipped with a full HD panning camera with a total view range of 270° that is ideal for inspecting confined areas.

It offers various tether options, extending up to 500 meters (1,640 feet), enhancing its versatility. Designed with a robust anodized machined aluminum body, the DTG3 ROV is engineered to withstand the most demanding conditions. Its adaptability also extends to industry-specific modular enhancements such as grabber claws, water samplers, and more, making it an adaptable tool for a variety of tasks.

The PHOTON is the ultimate portable “suitcase” ROV, weighing under 10 kg. Built with industrial-grade materials like carbon fiber and anodized aluminum, paired with magnetically coupled drives, stainless steel components, and acrylic lens cover ensure durability in the harshest conditions, making it the toughest micro ROV on the market.

The PHOTON is the ultimate portable “suitcase” ROV, weighing under 10 kg. Built with industrial-grade materials like carbon fiber and anodized aluminum, paired with magnetically coupled drives, stainless steel components, and acrylic lens cover ensure durability in the harshest conditions, making it the toughest micro ROV on the market.

With Deep Trekker’s BRIDGE technology to power it, the PHOTON offers users a lightweight option with advanced inspection capabilities. The rotating enhanced 4K camera, six thruster design for precise maneuverability, and ability to expand with additional tools and sensors, such as sonar, DVL, and USBL make this an ideal option for any ROV inspection operation.

Our team of seasoned industry experts are prepared to offer expert guidance and respond to any questions you might have regarding the incorporation of submersible robots into your operations. Whether your project involves tasks like water tank inspections and cleaning, salvage operations, underwater inspections, search and recovery missions, aquaculture initiatives, environmental monitoring, or any other specialized application, we stand ready to assist you in comprehending how our ROVs can seamlessly align with and fulfill your distinct needs.

When you're ready to secure your very own Deep Trekker vehicle, feel free to contact us, and we'll be happy to provide you with a customized quote tailored precisely to your needs. With Deep Trekker ROVs as part of your salvage diving operations, you can achieve unparalleled safety, efficiency, and success in your underwater recovery efforts.

November 3rd, 2025

At REPMUS 2025, Deep Trekker’s ROVs validated real-world mine countermeasure capabilities...

July 5th, 2025

Deep Trekker’s new Tampa facility brings faster ROV repairs, in-stock parts,...

June 11th, 2025

Equipped with sonar and DVL, Deep Trekker ROVs are helping SES...