Configure Now

Items in Your Cart0

0Items in Your Cart

Start building your packageShop Now

Southern Water Services of Texas utilizing a Deep Trekker Remotely Operated Vehicle (ROV) or underwater drone to conduct cooling tower maintenance.

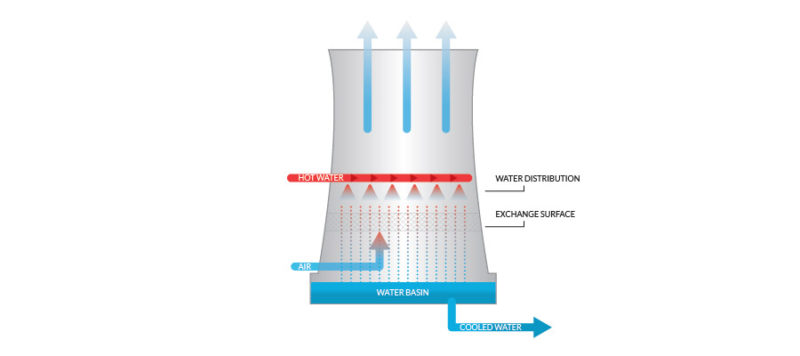

The cooling tower is a heat exchanger in which air and water are brought into direct contact in order to cool the water. The evaporation of water reduces the temperature of the water being circulated through the tower as a result.

Despite the numerous types of cooling towers used across a plethora of industries, the cooling tower working principles remain much the same. Evaporative cooling is the standard operating method of an industrial cooling tower. Hot water, gathered from numerous different processes around the plant, travels via pipe up to the top of the cooling tower where the water distribution systems are. As water enters into the cooling tower, it crosses over a group of spraying nozzles before being distributed onto the wet deck. In tandem, air is being drawn through air-inlet slats, forcing the water to evaporate. The evaporation process allows for the heat to be removed from the water, with the cooled water falling and the hot air rising naturally out of the tower. The cooled water is then pumped back out into the plant to be reused again.

Let us help find the right ROV for your underwater projects and applications

Additionally, without the cooling towers, large amounts of extremely hot water would return to the oceans, lakes, and rivers which may raise the temperature to the surrounding ecosystem. A cooling tower serves to dissipate the heat into the atmosphere, where it cannot be re-utilized, unless it falls in the form of rain, making it the far more ecologically friendly system. In order to maintain plant efficiency, both in terms of the systems operation and environmental regulations, these tanks must be monitored and cleaned regularly.

Another very important reason for the monitoring of cooling towers is to prevent the growth of legionella, a bacteria that causes Legionnaire’s disease. A common cause of Legionnaires is the inhalation of aerosols which are a by-product of cooling towers used in open recirculating evaporative systems. Monitoring and preventing this kind of bacteria is part of the strict regulations enforced on industrial complexes to ensure the health of its workers and surrounding communities.

Shutting down an entire industrial complex for cooling tower maintenance is next to impossible. Just an hour of downtime can cost millions of dollars in lost production. Being able to observe cooling tower conditions and schedule maintenance efficiently and cost-effectively is imperative. Southern Water Services of Texas, SWS, is a small company doing just that.

Created in 1992, the SWS team was formed to provide “knowledgeable service and advanced technology” to the water treatment market. Having worked and studied the field of water treatment for more than 40 years, SWS, recognized the growing need for a technology that could be introduced into cooling tower maintenance. Allowing for observation and monitoring, non-invasive cleaning and defouling, and the ability to deploy and act quickly.

After much research, Shelby Howell, VP of Operations at Southern Water Services of Texas, and his small team at SWS chose the DTG2, a Deep Trekker Remotely Operated Vehicle(ROV), to assist them in filling this gap and are now blazing a trail in water treatment community.

“The cooling tower is the heart of any industrial system - the ability to do strategic and regular segment shut downs - means the heart remains healthy and the system in operation,” advised Shelby.

November 3rd, 2025

At REPMUS 2025, Deep Trekker’s ROVs validated real-world mine countermeasure capabilities...

July 5th, 2025

Deep Trekker’s new Tampa facility brings faster ROV repairs, in-stock parts,...

June 11th, 2025

Equipped with sonar and DVL, Deep Trekker ROVs are helping SES...