Configure Now

Items in Your Cart0

0Items in Your Cart

Start building your packageShop Now

A deeper look into pipe crawler freewheel and the best ways to retrieve CCTV pipe inspection crawlers from municipal pipes. (Patent Pending)

Pipe inspections require tough systems that can withstand the grueling environments of municipal infrastructure. As the departments and contractors tasked with servicing these pipelines, it is extremely important to select a tool that stands up to the challenge.

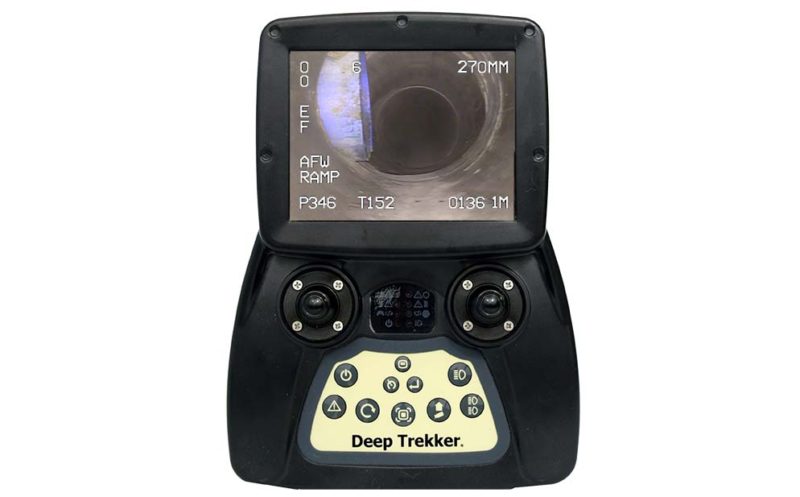

Today we are going to dive into one of the features unique to the DT340 Pipe Crawler system; showcasing one way our unique systems are the ideal tools for your pipe inspections. The Deep Trekker DT340 pipe crawler is very unique in the market. It is the only truly portable solution, requiring no topside power or dedicated trucks, everything is complete in two carrying cases.

Based on the same principles as our underwater ROV systems, our pipe crawlers have been designed with careful consideration to each step of the inspection process. One such consideration was finding the best way to quickly reverse the Deep Trekker™ DT340 pipe crawler once a pipe inspection is completed.

Most of the time in pipe inspections, there is not an area to retrieve the pipe crawler at the end, rather the system must reverse to the manhole from which it was originally deployed. This and other considerations—as always—come down to ensuring Deep Trekker™ products are the most portable, simple to use, robust and affordable products available. With this in mind, we set out to create a sleek and lightweight system that minimizes any sort mechanical complexity, while still providing an efficient way to bring the pipe crawler back through the pipe.

Active Freewheel (Patent Pending) is a smart technology designed to sense when an operator is pulling back the tether and actively engages the wheels to reverse and aid in a smooth and effortless retrieval.

Active Freewheel (Patent Pending) is a smart technology designed to sense when an operator is pulling back the tether and actively engages the wheels to reverse and aid in a smooth and effortless retrieval.

For example, when an inspection is complete the operator will simply press the Cruise Control (CC) button to engage the pipe crawler Freewheel function. After pulling the tether back, the DT340 pipe crawler will provide power-assist and reverse the wheels, making the system very easy and lightweight to recover from the pipe.

If you are looking for the fastest way to bring your DT340 pipe crawler out of the pipe, HOLD mode will reverse the pipe crawler at full speed after pulling the tether. The operator can set the function and then, once ready, begin the automatic top speed reverse of the crawler once they pull back on the tether.

If you are looking for the fastest way to bring your DT340 pipe crawler out of the pipe, HOLD mode will reverse the pipe crawler at full speed after pulling the tether. The operator can set the function and then, once ready, begin the automatic top speed reverse of the crawler once they pull back on the tether.

In this situation, the pipe crawler will automatically reverse at an ideal speed for the operator to reel the tether onto the reel. With this option, one person can complete an inspection and have their reel and tether ready to pack up after retrieving the pipe crawler.

The crawler will automatically switch to RAMP mode once the tether counter distance goes under 2.5 m (8.2 ft). At the beginning of the inspection the operator sets tether counter 0 meters (feet) at the edge of the pipe, so now the system will automatically know when the vehicle is reaching the end. This will allow the vehicle to gradually slow down as it reaches the manhole.

At any time, the operator can switch between HOLD and RAMP mode, by pulling the left joystick downward to HOLD, or upwards back to RAMP. The on-screen display indicates the active modes.

Talk to us about your pipe inspection projects

Unique Feature: The DT340 Pipe Crawler system can still steer while in Active Freewheel RAMP or HOLD modes.

While on the return, the PTZ camera head can rotate to look at the DT340 pipe crawler’s back tire; providing the ability to actively steer around obstacles or uneven terrain. While in either RAMP or HOLD mode, the crawler may steer left or right for small course corrections.

Related Story: What makes the DT340 so special?

This was a quick overview of Active Freewheel, to see more unique features of the DT340 click here. Or contact our knowledgeable CCTV crawler professionals today to learn more about the DT340 pipe crawler system.

November 3rd, 2025

At REPMUS 2025, Deep Trekker’s ROVs validated real-world mine countermeasure capabilities...

July 5th, 2025

Deep Trekker’s new Tampa facility brings faster ROV repairs, in-stock parts,...

June 11th, 2025

Equipped with sonar and DVL, Deep Trekker ROVs are helping SES...