Configure Now

Items in Your Cart0

0Items in Your Cart

Start building your packageShop Now

As Notre-Dame de Paris officially reopens its doors to the public following years of meticulous restoration, a lesser-known but critical component of the project is now being recognized: the use of advanced pipe crawler technology to support the cathedral’s acoustic preservation efforts.

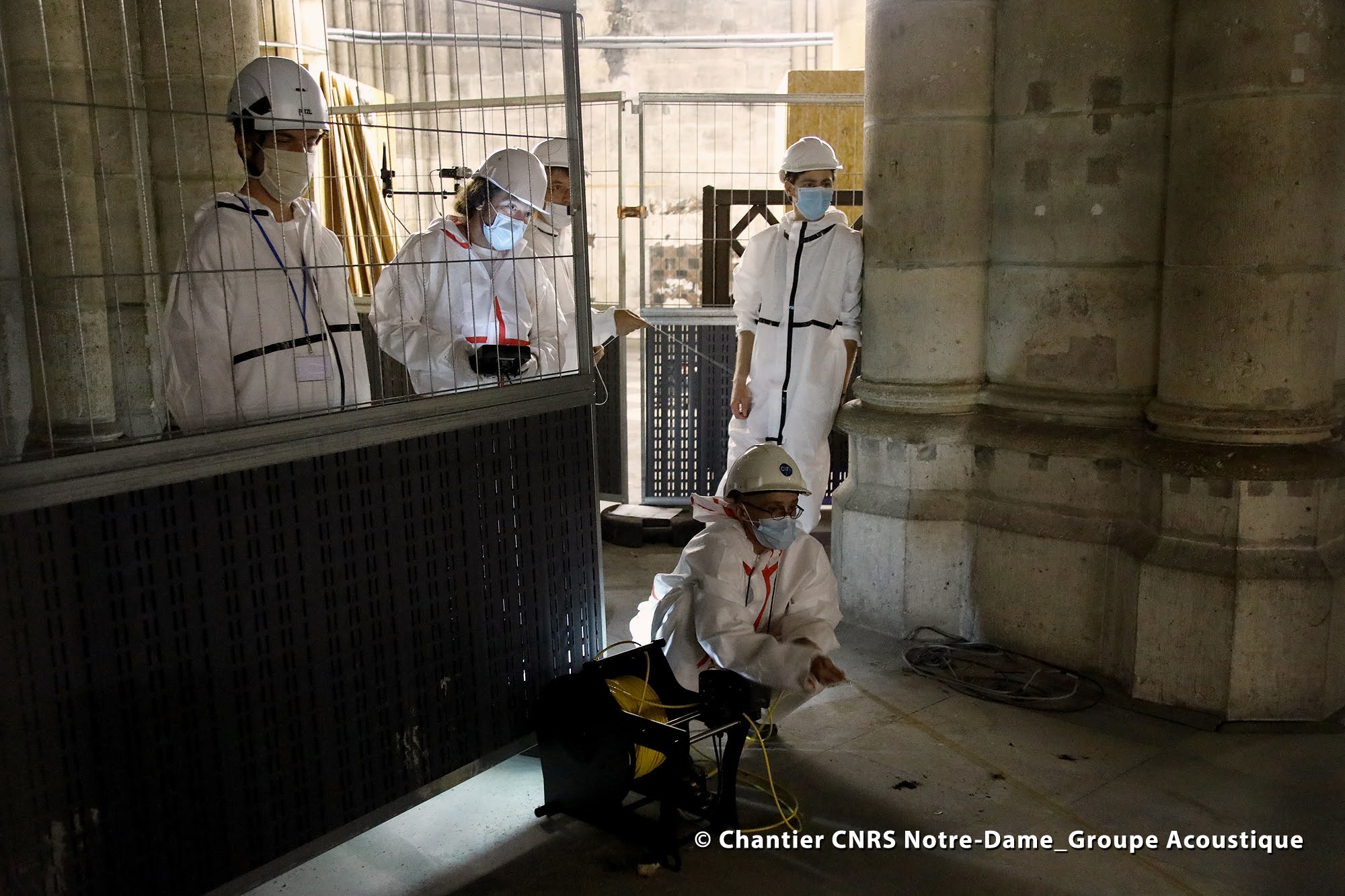

Provided by Deep Trekker Inc. and deployed by French drone inspection firm Escadrone, the Pipe Trekker A-200 pipe crawler enabled researchers from CNRS (Centre National de la Recherche Scientifique) to access hazardous and obstructed areas within the fire-damaged structure. Their goal was to analyze the building’s soundscape in support of restoring the cathedral’s unique acoustics.

“For our work in Notre-Dame cathedral, right after the fire, we were confronted with a new challenge,” explains Brian FG Katz, Research Director at CNRS. "We needed to be able to position our measurement equipment remotely, due to safety concerns. The Pipe Trekker met our needs remarkably well, being able to pull several wheeled instrumentation setups easily and precisely.”

Notre-Dame de Paris, a symbol of French heritage and one of the most recognized examples of Gothic architecture in the world, was badly damaged by fire on April 15, 2019. The fire destroyed the spire and roof, and led to extensive damage inside the nave and upper structure. Efforts to stabilize, assess, and eventually restore the cathedral have involved international collaboration across engineering, architecture, and historical preservation fields.

Following five years of restoration work, the cathedral officially reopened to the public on December 8, 2024.

As part of the broader restoration strategy, CNRS researchers focused on the acoustic character of the space - an integral element of its cultural and liturgical function. Notre-Dame’s sound environment is shaped by centuries of architectural evolution, with reverberation patterns that affect everything from Gregorian chant to the organ's resonance. Understanding and preserving these acoustic properties became a key priority.

The reverberation time in Notre-Dame before the fire was measured at around 6 to 7 seconds in the nave - an unusually long decay time that contributes to the cathedral’s deep, immersive sonic environment. This acoustical fingerprint is shaped by the building’s size, stone surfaces, vaulted ceilings, and architectural symmetry.

After the fire, structural instability made it impossible to enter some sections of the nave and transept safely. These inaccessible zones contained valuable acoustic data that needed to be gathered before restoration progressed further. Accurate models of pre- and post-fire reverberation would allow engineers and designers to adjust their restoration approach to preserve this unique sonic footprint.

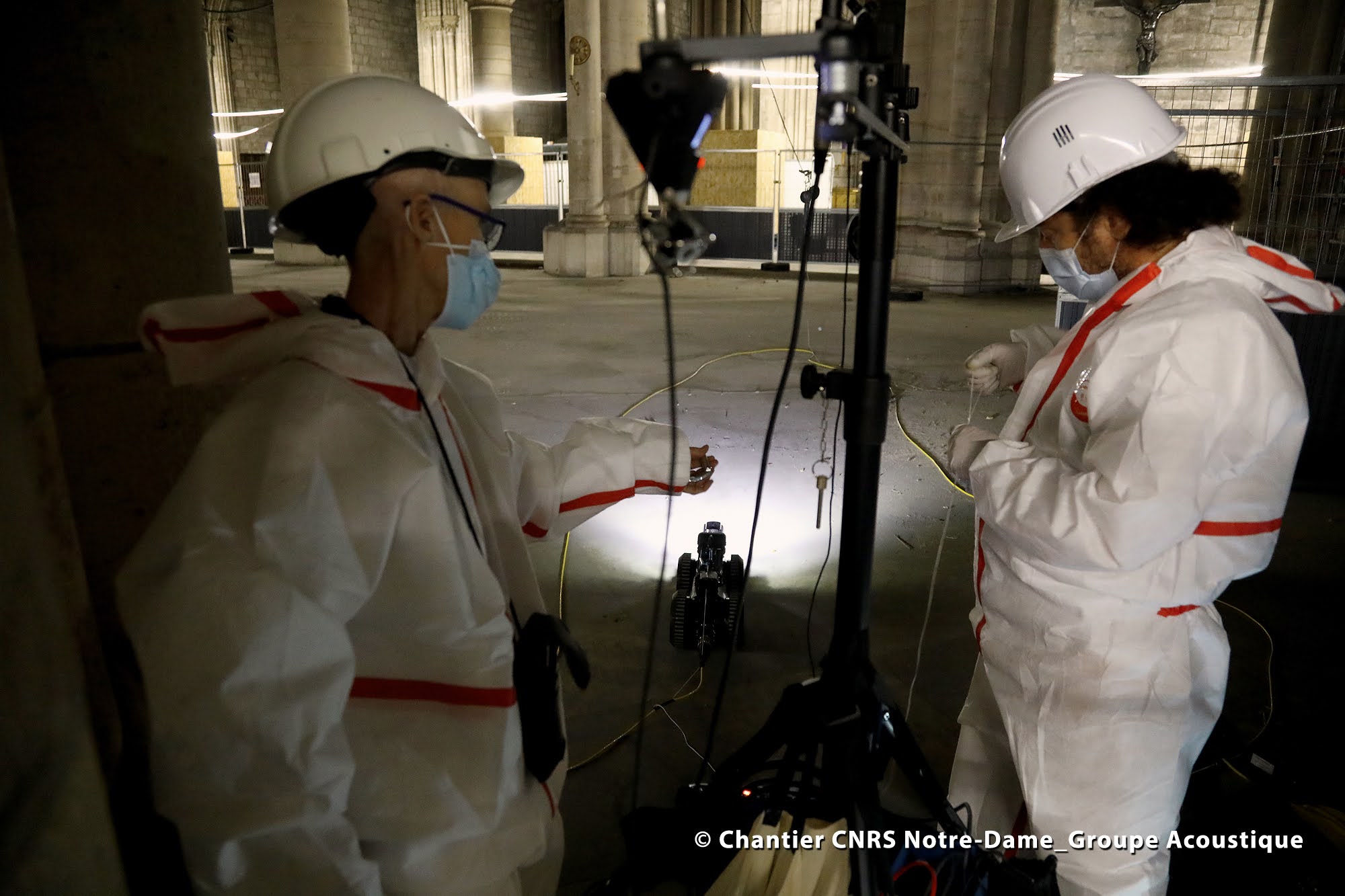

To overcome these access challenges, CNRS partnered with Escadrone to deploy the Pipe Trekker A-200, a battery-powered, portable pipe crawler built by Deep Trekker Inc. The crawler was selected for its compact size, robust construction, and ease of deployment - features crucial for navigating the structurally fragile interior of Notre-Dame.

With just two cases and a one-minute deployment time, the A-200 provided quick and non-invasive access to blocked passageways and elevated structures. Its 8-hour battery life and rugged aluminum-and-steel construction allowed it to traverse the length of the nave inside the cathedral.

The A-200 enabled teams to:

The crawler was equipped with customized accessories for increased traction and stability in unpredictable terrain. These included wide tire configurations and puncture-resistant air-filled tires designed for maximum control inside unstable and debris-filled environments.

“The onboard camera and headlight provided immediate feedback, which was a significant help during the task, noted Katz. “And the pulling power and traction of the Trekker easily met our requirements.”

This mission was more than just scientific - it was cultural. By documenting the acoustic environment of Notre-Dame during its most vulnerable state, the CNRS team created an auditory archive of the cathedral's sound signature, offering insight into how structural damage and restoration influence acoustics.

The data collected with the help of the Pipe Trekker A-200 has been used to refine digital models of the cathedral’s interior sound behavior. These models support reconstruction decisions, helping ensure that the restored Notre-Dame will sound - as well as look - true to its original character.

The success of the Pipe Trekker A-200 deployment at Notre-Dame illustrates how modern robotic tools can contribute meaningfully to historical restoration. While originally designed for municipal and industrial pipe inspections, its adaptability allowed it to assist in one of the most iconic architectural recovery efforts in modern history.

Commenting on the vehicle's ease of use, Katz said, “The driving controls were intuitive - we picked it up quickly after the brief introduction and training session provided by Escadrone.”

As the cathedral begins a new chapter - welcoming worshippers, visitors, and music once more - the work done in its silent, scorched halls by a humble inspection crawler highlights how precision technology can help preserve not just structures, but the experience of sound within them.

Need a Crawler for Confined Space Inspections?

Modern pipe crawlers like the Pipe Trekker A-200 offer reliable, high-resolution visual access to environments that are otherwise unsafe, impractical, or physically inaccessible. While originally designed for municipal and industrial pipe inspections, these systems are increasingly used across multiple sectors due to their adaptability and durability.

Traditional manual inspection methods are often unsuitable for confined spaces due to health and safety risks, restricted maneuverability, and lack of visibility. Pipe crawlers mitigate these issues by enabling remote visual inspections in:

Beyond traditional pipework, the A-200 is also suited to more specialized roles. Some examples include:

These environments demand robust data acquisition without compromising safety. The A-200’s onboard camera systems and optional sensors support both real-time monitoring and recorded data for post-inspection analysis.

In mining and heavy industrial applications, pipe crawlers can be used to inspect:

In these cases, early identification of leaks, blockages, or structural deformation reduces downtime and supports proactive maintenance planning.

The A-200 is equipped with high-resolution cameras and optional sensors (e.g., laser profiling, temperature, inclination), enabling operators to gather quantitative inspection data.

This level of detail supports:

The result is actionable intelligence for engineers and asset managers, reducing the risk of service disruption and allowing for targeted repairs rather than broad, costly interventions.

Deploying a pipe crawler in place of manual inspection methods results in several measurable advantages:

For more information about the Pipe Trekker A-200 and our robotic solutions, including detailed specifications and use cases, visit our website.

November 3rd, 2025

At REPMUS 2025, Deep Trekker’s ROVs validated real-world mine countermeasure capabilities...

July 5th, 2025

Deep Trekker’s new Tampa facility brings faster ROV repairs, in-stock parts,...

June 11th, 2025

Equipped with sonar and DVL, Deep Trekker ROVs are helping SES...