Configure Now

Items in Your Cart0

0Items in Your Cart

Start building your packageShop Now

A typical hydroelectric plant is a system with three parts: a power plant where the electricity is produced, a dam that can be opened or closed to control water flow, and a reservoir where water is stored. The water behind the dam flows through an intake and pushes against blades in a turbine, causing them to turn. The turbine spins a generator to produce electricity. The electricity can be transported through long-distance electric lines to homes, factories, and businesses.

Consistent inspection and subsequent maintenance of hydroelectric plants is imperative for safe, efficient and effective operation, however there are risks involved in inspection - particularly for underwater components.

Humans have a long history of using the force and power of water running in streams and rivers to produce mechanical energy. Hydroelectric dams allow people to take advantage and harness all of this power. These complicated structures contain various components and structures that may vary to suit the water source. Despite their differences the primary goal of hydroelectric dams is to collect water, run that water through a turbine to turn the turbine and generate energy, then deliver that water out the other side. To actually move water through the turbine it first goes through a pipe, or penstock, which then drives the water through the turbine blades to actually spin those blades to produce electricity.

A water intake is an integral part of power generation and is directly responsible for the water flow efficiency coming into the dam from a stream, river, lake or reservoir. The water intake is right at the front of the penstock where water enters the dam. Water intake gates and screens protect vital components within the dam such as the turbines, pumps, and pipes from damage which can be caused by debris, sediment, invasive species, fish, and ice. In order for hydro-electric dams to generate power at the highest capacity, each aspect of the system requires periodic inspection and maintenance

One of the most common causes for diver deaths is differential pressure, more commonly known as Delta P. Delta P refers to pressure drops in the water, particularly across a piping component such as a valve or filter. Water moving from an area of high pressure to one of low pressure, such as when an opening is created on one side of a hydroelectric dam, can create enough force to trap divers against intakes. Delta P is a major problem for divers - particularly when it comes to underwater intakes. The pressure created can be in the tonnes, trapping divers, often with tragic results. Furthermore, these vacuums can be difficult to detect until it’s too late. While Delta P is a risk for divers in all circumstances, from underwater construction to inspection, it is especially prevalent near water intakes due to the pressure changes.

There are many other dangers associated with coming too close to hydroelectric dams and stations, which are applicable not just for commercial divers but for swimmers, recreational divers and boats as well. Hydroelectric dams are well marked and monitored for a reason! Risks associated with being in the water near a dam include;

Let us help find the right ROV for your underwater projects and applications

Due to their popularity and the historical use of hydroelectric power, many dams are rapidly aging. As years pass, the underwater structures in these dams face several integrity issues.

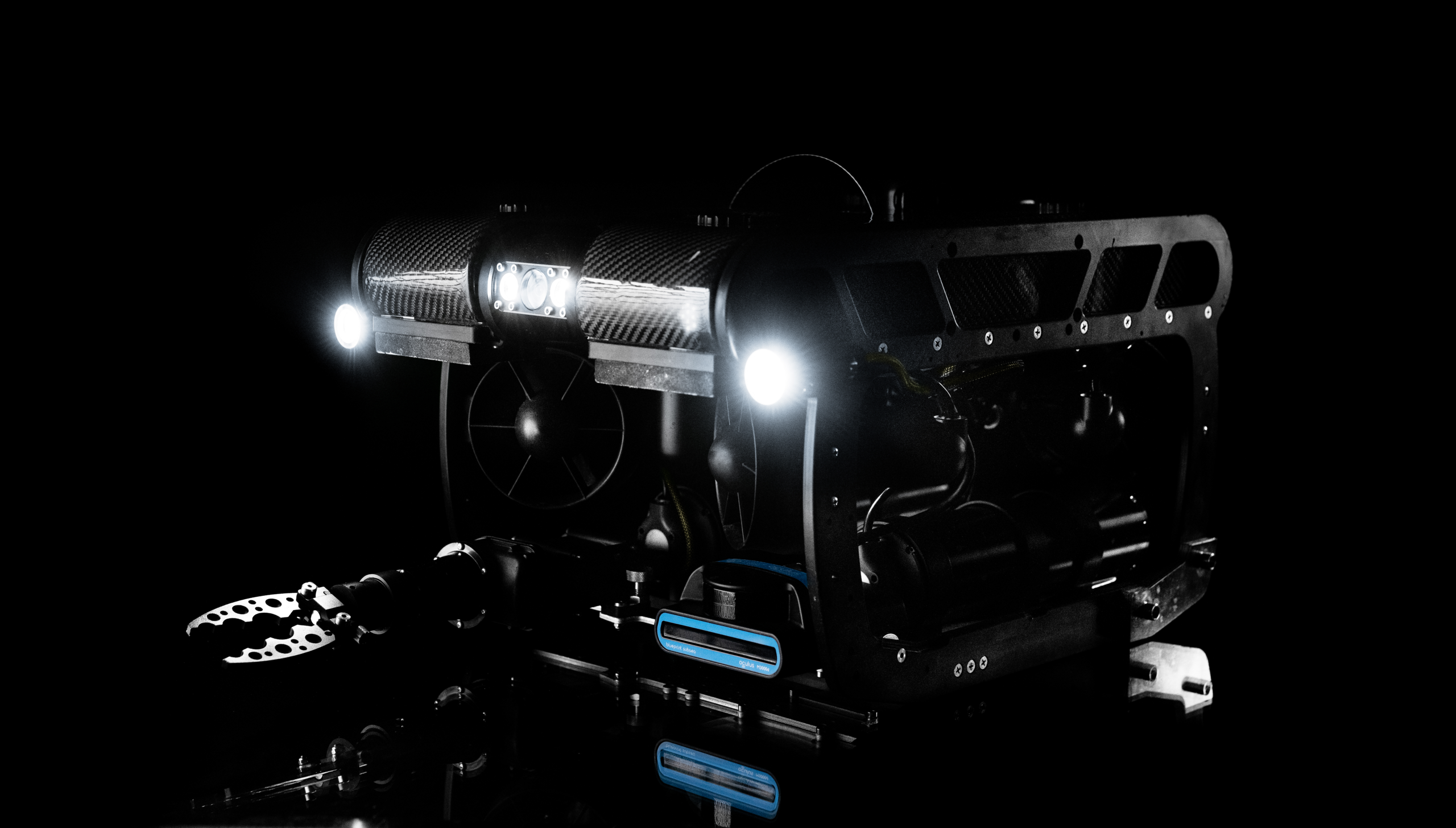

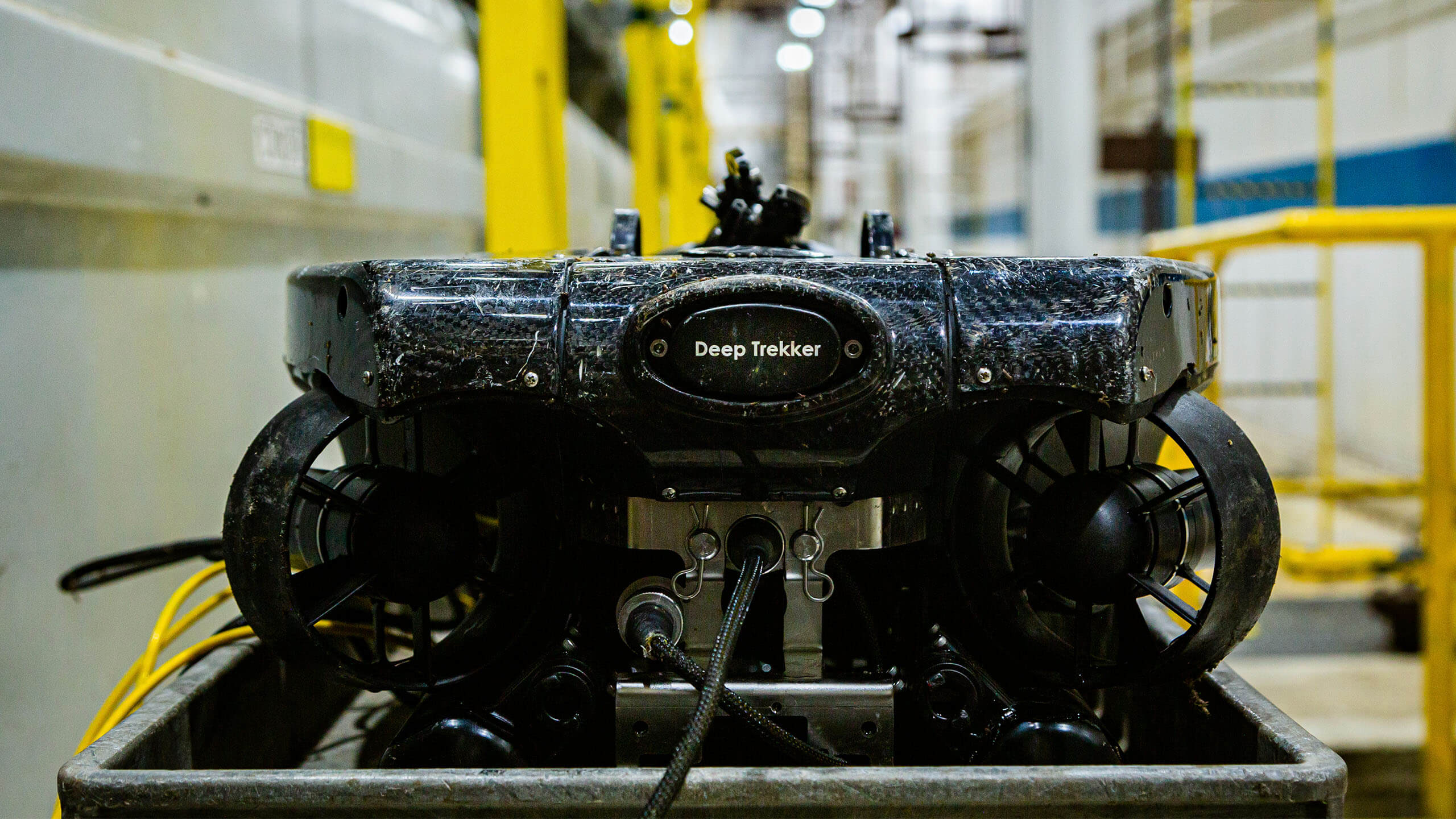

Using submersible remotely operated vehicles or ROVS for underwater maintenance and inspection on underwater structures allows teams to save significant amounts of both time and money, while keeping human divers safe.

Maintenance teams simply deploy the camera-equipped vehicles to be able to safely inspect all underwater structures. Operated with the handheld controller, ROV pilots get a live view of their submerged infrastructure, as well as the ability to record collected data.

Once maintenance activities have been ascertained, Deep Trekker ROVs are ideal to launch again in unison with a diver. Here the HD camera can monitor the safety of the diver while they work, in addition to collecting other relevant data from the work site that can be historically cataloged and utilized for future planning activities.

The primary benefits of Deep Trekker ROVs for underwater dam maintenance include;

Deep Trekker has embarked on a mission to provide safe, cost-effective and efficient tools for underwater observation. As the pressures to find cost-effective methods to maintain our world's aging infrastructure; Deep Trekker has expanded its product offerings to continue providing innovative and purpose-built inspection robots for your next underwater inspection.

As always, our team of experts is available to answer any questions you may have. If you’re ready to take the leap and get a vehicle of your own, reach out to get your customized quote today.

July 30th, 2021

Learn all about remotely operated vehicle pilots: how to become one,...

November 5th, 2024

Learn more about what sonar is and its many uses. Read...

December 23rd, 2021

ROVs and sonar can be used to inspect underwater structures such...