Request a Quote

Items in Your Cart0

0Items in Your Cart

Start building your packageShop Now

We are aware that pipes exist and we are aware that there are sewer and drinking water pipes. We receive clean water for showers and washing dishes, then flush our toilets and do our laundry. But we don't invest much time thinking about what happens beyond this.

We've provided a crash course on the various networks of pipes running in concert with road networks - water pipes, drinking water, sewage water and stormwater.

Decades ago, storm and sewer pipes were often combined. This increased the likelihood and severity of sewer backups and floods. Floods and sewer backups can cause health scares and are extremely important to avoid.

An important part of maintaining public health, avoiding costly repairs and protecting the environment is to regularly inspect infrastructure. Infrastructure is deteriorating and inspections are critical to help prioritize where scarce resources for repairs are put into action. The best practice of maintaining these pipe networks in the 21st century is to inspect the entire network, noting which pipes are in the worst condition and which require immediate repair.

Although this sounds simple - "throw a camera in those pipes!" - well not so fast ... how many people can tell exactly what can go wrong in a pipe, what is catastrophic or what can be put off? The good news is that there are resources to help with this. In North America, we use a system called PACP, brought forth by an organization dedicated to water infrastructure, NASSCO.

NASSCO set out on a mission to define various defects within a pipe and has been successful with over 20,000 members using their standards as they inspect pipes. They designed a course that shows the types of defects - tree tops infiltrating pipes, pipes becoming disjointed, collapses, etc. They also use a numerical code (1-5) to determine the severity of a defect and the difference between each defect range.

The next step is thinking about the end goal of a pipe inspection, what needs to be done and what is the best way to approach it. When inspecting a large network of pipes, you want to be able to figure out where the worst areas are and focus on this first. When you repair a pipe, either by excavating (digging a hole) or by using trenchless technologies such as pipe lining, you are involving manpower and equipment. It is far more efficient to deploy these resources into areas with multiple tasks then to continually deploy for individual jobs.

Talk to us about your pipe inspection projects

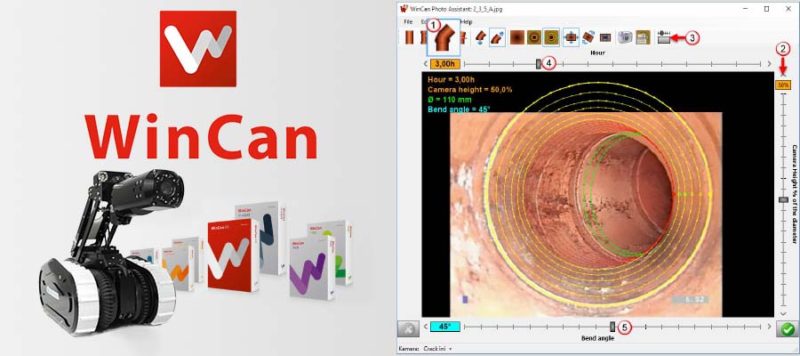

WinCan’s software program operates from a computer, either simultaneously or after the inspection video is taken. The video is delivered from the camera device (a pipe crawler in this case) and is recorded by the program.

You can also name a pipe, identify its attributes (diameter, type of material, etc) and log where the defects are located, its severity and repair strategies. The software compiles this data in an easy to digest format. It also gives you a report in NASSCO compliant format to allow you to view yourself, or deliver to a customer whom you are inspecting for. In some modules of WinCan, you can tag pipes onto a GIS (Geographical Information System) map. The map allows you to visualize where "hot spots" are located or in other words where the majority of your repairs are required.

July 30th, 2021

Underwater drones were first invented in the 1950s. Their design enabled...

April 6th, 2021

Sonar systems have many applications, but what should you know? This...

December 23rd, 2021

ROVs and sonar can be used to inspect underwater structures such...